Technical Data

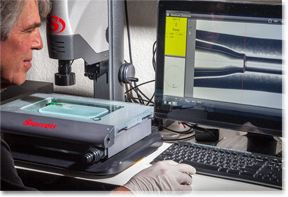

Farlow’s Scientific Glassblowing is known for working with our customers to bring ideas to fruition and create advanced  research development tools. We continually maintain and upgrade our production facility with state-of-the art equipment and the latest technologies, enhancing our expertise with a variety of techniques and applications including:

research development tools. We continually maintain and upgrade our production facility with state-of-the art equipment and the latest technologies, enhancing our expertise with a variety of techniques and applications including:

Typical Applications:

- Angioplasty/stent delivery balloon molds

- Tipping dies

- Capture sleeves and tubes

- Analytical apparatus fabrication

- Anatomical models

Specialized Techniques:

- Eccentric/concentric centers

- Precision drilling, boring, cutting, grinding

- Custom tooling

- Acid cleansing and re-sizing

- Graded thermo-expansion seals

Production Capabilities:

- Prototyping

- Research and development runs

- Low- and high-volume manufacturing

Size Ranges/Tolerances:

- Standard tubing sizes in stock

- Inside diameters down to .010 inches

- Outside diameters up to 4 inches

- Small diameter ID tolerance accuracy to 0.0002”

Custom Sizes and Shapes:

- Converging or diverging flares

- Formation of “custom” cross sections

- Tapered, stepped or offset internal and external dimensions

- Cross sections: circular, rectangular, square, half-circular, flats, etc.

Standard Tolerances:

These dimensions apply to medical products with inside diameters below .250”.

ID: +\- .0005”

SL: +\- .010”

TL: +\- .010”

OL: +\- .040”

OD Grinding Tolerances:

We currently have the capability of grinding parts up to 4” in length. These dimensions are based on the OL with the part that is being ground:

Parts with lengths up to:

4” Length – OD tol. of +\- .003”